Wastewater Treatment

Aeration Systems for Municipalities, and Industry

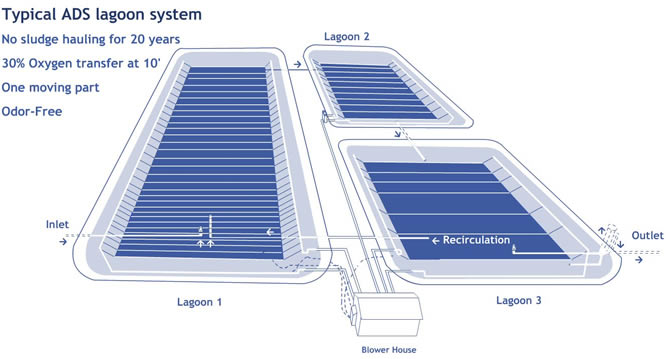

EP Aeration is proud to be the California representative for Air Diffusion Systems (ADS). Together we work with engineers, consultants, and operations managers to provide wastewater treatment systems for municipalities, food and beverage processing facilities, and aquaculture. ADS systems feature some of the highest oxygen transfer efficiencies in the industry. Our systems are about 3-5 times more energy efficient than mechanical surface aerators that have traditionally been used in the Aerated Facultative Lagoon process. This energy efficiency typically qualifies our clients for significant incentives and rebates through their energy purveyors. Furthermore, our complete systems are backed by a five year guarantee to be odorless and meet treatment requirements. Between ourselves and our vast network of distribution, engineers, contractors and specialists, we have the resources to see your project through from beginning to completion. Click here for a free quote or scroll down for more information.

As the graph above indicates, significant energy savings can be realized by switching from a surface aerator to an ADS sub-surface, fine bubble aeration system. In fact, we can save you enough energy to qualify you for a rebate from your energy purveyor.

Niner Wine Estates, Paso Robles, CA:

Niner Wine Estates is one of the most environmentally progressive wineries in the world. In addition to achieving Silver Leed Certification for the tasting room and winery, the owner and engineers took additional steps to reduce its impacts to onsite water resources. EP Aeration and ADS designed an efficient winery wastewater treatment system that would achieve water quality fit to supply all of the property’s landscape irrigation and 15% of the vineyard crop demand.

We were able to achieve this while reducing their yearly energy costs by roughly $17,000 per year versus surface aeration. EP Aeration also facilitated a rebate of 10% of the capital cost of the system for the energy savings. This compelling project was featured in land and water management publications click here to read them.

Metolius Municipal Wastewater Treatment Facility, Metolius, OR

In 2011, the city of Metolius was looking for ways to improve treatment and save electricity at its wastewater treatment plant. After careful evaluation, the city selected Air Diffusion Systems fine bubble aeration to replace its eight – 5 horsepower surface aerators. ADS designed a system that operates at only 7.8 Brake Horsepower thereby reducing their energy usage by 32.2 horsepower and reducing their annual operating costs by $10,500 – $13,000.

Chamisal Vineyards, Edna Valley, CA:

In 2012, Chamisal Vineyards approached engineers at the Wallace Group regarding a desire to increase production from 30,000 to 100,000 cases of wine per year. Of course this increase in production would increase wastewater flows as well. EP Aeration and ADS worked with the winemaker and engineers to retrofit the existing lagoon by replacing the existing surface aerators with ADS fine-bubble aeration, using only 13 brake horsepower. ADS also specified a VFD and PLC to operate the blower at slower speeds during the off-season, thereby reducing energy usage even further. The system will eventually be outfit with a dissolved oxygen sensor for complete automation and energy optimization.